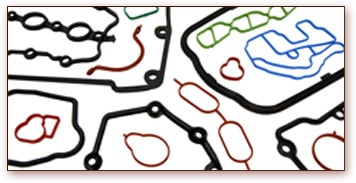

ENA Advanced Rubber Technologies is a renowned global leader in providing custom OEM rubber gaskets. Our experience in producing gaskets initially catered to the automotive and motorcycle industries. We have since expanded our markets and customer base for high precision and close-tolerance complex rubber gaskets. While our expertise has diversified, we remain unrivaled in producing top-quality engine and oil pan gasket sets for auto and motorcycle applications.

Our custom gaskets are manufactured across all four of our facilities in Asia, ensuring complete control over the production process. We formulate our rubber compounds in-house and produce all tooling, guaranteeing exceptional quality. ENA boasts the widest range of compression molding presses in Asia, including presses up to 900 tons capable of producing gaskets up to 1.3 meters in diameter (approximately 4.2 feet). In addition to solid rubber gaskets, we excel in manufacturing over-molded metal gaskets and bonded rubber-to-metal elastomer flat metal gaskets.

ENA stands out by offering cost-effective tooling and unbeatable lead times for rubber gaskets. We can work with existing drawings, prints, or samples, and even reverse engineer your parts. Our highly efficient engineering and tooling departments ensure a seamless transition from concept and quotation to production.

Experience the quality and efficiency of ENA’s rubber gaskets. Contact us today to discuss your requirements and benefit from our unparalleled expertise in the industry.