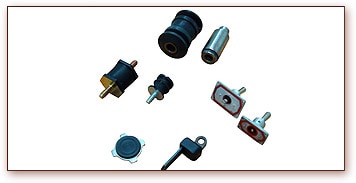

With decades of experience, ENA Advanced Rubber Technologies is a leading manufacturer of custom OEM bonded rubber-to-metal parts. We pride ourselves on our unrivaled knowledge of the processes and methodologies required to produce top-quality parts in the industry.

Each rubber bonded part and its bonding process are unique due to the varied formulations and ingredients of rubber compounds. At ENA, we perform all material compounding in-house, giving us a deep understanding of rubber formulations and their physical properties. Furthermore, we handle the cutting and processing of metallic parts entirely within our facilities, ensuring meticulous control over surface contamination and cleanliness. This attention to detail is crucial for achieving long-lasting, high-quality bonds, as we remove residues like cutting oil that can compromise the bond’s integrity.

With in-house plastic injection molding, ENA has the capability to produce intricate rubber bonded to plastic parts. ENA boasts a dedicated team of chemists across all our factories who possess in-depth knowledge of the polymeric blends used to bond rubber to metal or plastic. The process of effectively bonding rubber to metal or plastic goes beyond simple “gluing.” It involves utilizing different processes, materials, adhesives, and chemicals based on the specific rubber compounds and metallurgies and plastic compounds involved. Bonding rubber to metal is a specialized and intricate process, and ENA excels in this field of manufacturing.

For premium quality rubber-to-metal bonded parts, rely on ENA Advanced Rubber Technologies. Contact us today to discuss your requirements and experience our expertise firsthand.