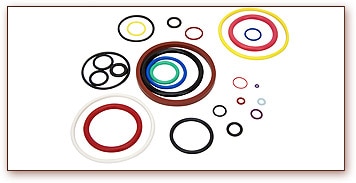

ENA Advanced Rubber Technologies has been producing o-rings since 1978. While we are a leading supplier of stock off-the-shelf AS568B size o-rings, our true expertise lies in manufacturing custom engineered o-ring products. Whether it’s challenging sizes or complex rubber formulations, we excel in delivering hard-to-produce o-rings. Our capabilities extend to providing secondary services like Teflon coatings and “two-color” rings.

At ENA, we prioritize advanced machinery and equipment for secondary operations and maintain strict quality control measures. Our Cryogenic Nitrogen De-Flashing and Stone Tumbling machines ensure precise finishing and optimal surface quality for o-rings and rubber parts.

With numerous o-ring manufacturers and suppliers worldwide, ENA stands apart with our unwavering commitment to quality and custom engineered parts. We go beyond simply offering low-cost options by providing advanced capabilities that meet critical application requirements. Count on ENA for the highest quality and consistent o-ring parts, backed by our guarantee. If you’re facing challenges with existing parts or suppliers, contact us for reliable solutions. Experience excellence with ENA Advanced Rubber Technologies.